|

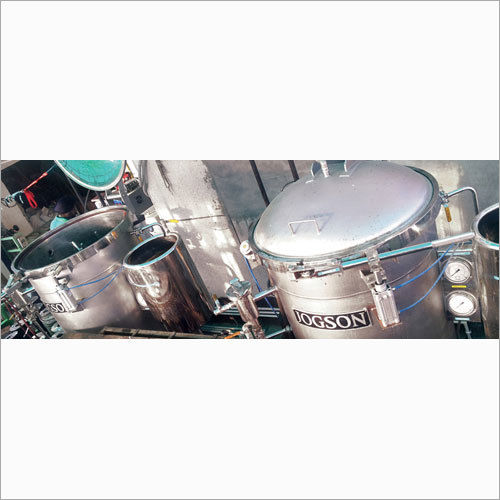

HTHP Horizontal Tubular Yarn Dyeing Machine

Product Details:

- Power 3 - 25 kW Watt (w)

- Type HTHP Horizontal Tubular Yarn Dyeing Machine

- Voltage 220-440 Volt (v)

- Applicable Material AISI - SS 316 L

- Weight 100-500 Kilograms (kg)

- Click to View more

HTHP Horizontal Tubular Yarn Dyeing Machine Price And Quantity

- 1 Unit

- 702000.00 INR/Unit

HTHP Horizontal Tubular Yarn Dyeing Machine Product Specifications

- HTHP Horizontal Tubular Yarn Dyeing Machine

- 3 - 25 kW Watt (w)

- AISI - SS 316 L

- 100-500 Kilograms (kg)

- 220-440 Volt (v)

HTHP Horizontal Tubular Yarn Dyeing Machine Trade Information

- Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque Cash Advance (CA)

- 1 Unit Per Month

- 1 Week

- All India

Product Description

HTHP Horizontal Tubular Yarn Dyeing Machine, its body and other functional parts are made from optimal quality steel and are totally corrosion resistant. The machine has the capacity to hold out a vacuum pressure that produces cold drenched steam. Offered machine is available with a maintenance free mono block vacuum pump, which enable vacuum gain as well as uniform absorption of moisture. Provided with the processes of direct & indirect heating, jacket cooling and others, it ensures an efficient operation on all types of surrounds. Provided with a pneumatic operated door lock as well as safety interlocks, the HTHP Horizontal Tubular Yarn Dyeing Machine ensures uniform & dependable operation as well as variable yarn loading, every time.

Feature

Advantages

- Compact arrangement of JOGSON turbo pump, Heat exchanger and piping is the main key to floor space saving

- Ultra Low MLR of 1:3, consumes less dyestuff, chemicals, steam, water & produces less effluent discharge, hence it's ECO friendly & reduces the Production Cost

- Inverter driven turbo pump for variable flow control; saves upto 40% power consumption hence more Energy Efficient

- HT drain at 130 Degree C for oligomers elimination during polyester dyeing process

- Variable loading with dummies maintains constant MLR & flow rate

- Working platform is not required as the top most tube in which the carrier is to be loaded is at the height of 1.5 mtr approx

- Overhead hoist need not to be installed as the carriers are loaded from front in the machine

- Excellent dyeing result and levelness, reduces yarn loss

- Water level, pressure, distinctive temperature multiple safety interlock, ensures operational safety

Technical Data

- Maximum design pressure 5 bar

- Maximum design temperature 140 Degree C

- Heating gradient 25 Degree C - 130 Degree C approx at 5 Degree C /min. (Dry Saturated steam pressure at 7 bar)

- Cooling gradient 130 Degree C - 85 Degree C approx at 3.5 Degree C/min. (Cold water of 25 Degree C at 3 bar)

Other Products in 'Yarn Dyeing Machine' category

|

JOGINDRA INDUSTRIES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |